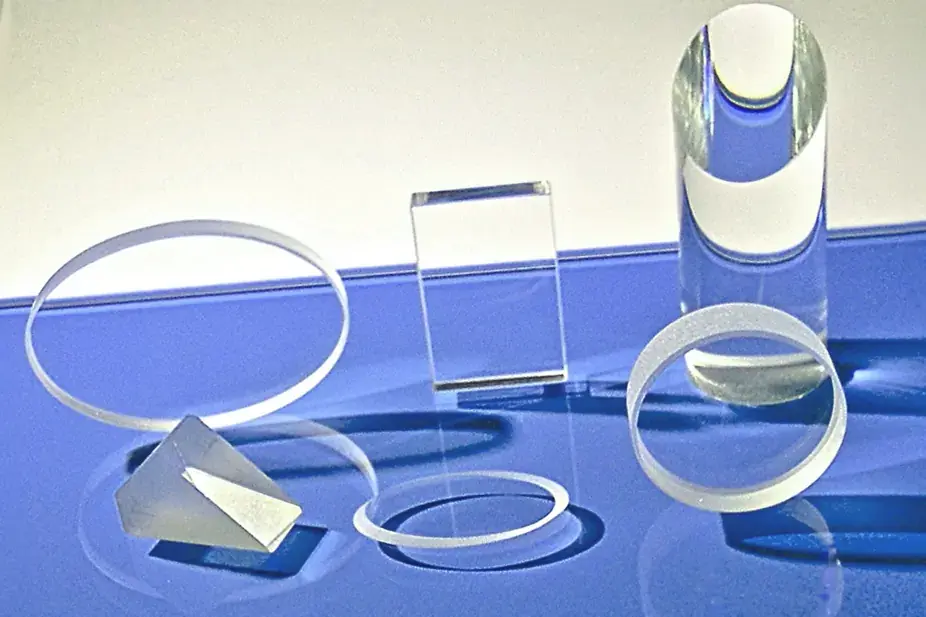

Precision Quartz Glass Manufacturing for Semiconductor, Optics & Industrial Applications

Custom fused silica and quartz components for semiconductor tools, optical systems, photovoltaic and LED production, laboratory equipment and industrial process lines. Engineered for vacuum, plasma, UV and high-temperature environments, with precision machining, tight tolerances, cleanroom packaging and reliable global delivery.

ISO 9001–ready

<±0.05 mm tolerances

Clean packaging level up to ISO Class 5

Engineered Quartz for Vacuum, Thermal, and Harsh Environments

Custom fused silica components for vacuum systems, plasma and UV processes, high-temperature furnaces, analytical instruments, and industrial equipment. Stable performance, clean surfaces, and documented traceability from prototype runs to volume production.

We supply equipment builders, OEMs, and labs with dependable quartz components.

Quartz Products & Capabilities Tailored to Your Application

From standard tubes and plates to complex, multi-port assemblies, we machine, polish, seal, and package to your specification.

Quartz Product Families

Fabrication & Finishing We Offer

From RFQ to Qualified Parts—Fast and Controlled

1. Send RFQ

Share drawings/specs (OD/ID/Length, tolerances, ports/flanges, environment, quantity) and any reference photos.

2. Engineering Review & Quote

We confirm feasibility, material grade, surface finish, and provide lead time & pricing.

3. Manufacture, Inspect, Deliver

Machining, sealing, annealing, and full QC with packaging suitable for your line.

Results / Case Snippets

Selected Deliveries

客户产品说明

客户产品说明 客户产品说明

客户产品说明

Have Questions or an RFQ?

We’re here to help. Share your drawings/specs for a fast, accurate quote and engineering feedback.